SOMIC ReadyPack - The cartoner for entry into fully automatic end-of-line packaging

Fast and cost-effective cartoner for standard packaging tasks

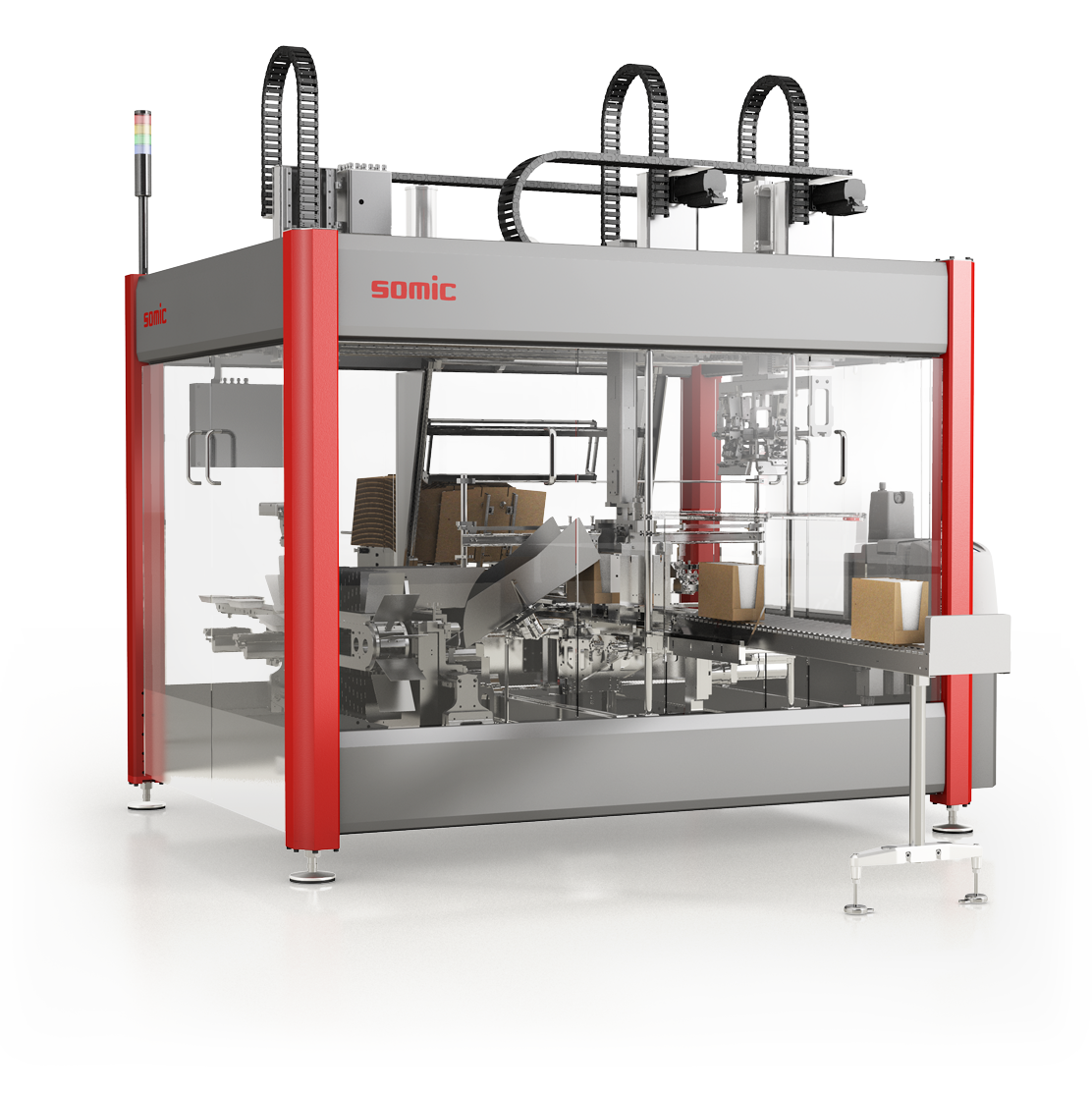

Our SOMIC ReadyPack is the ideal packaging machine for entry into automated end-of-line packaging. The compact machine is designed for one-piece carton packaging and is suitable for pre-packed products from a wide range of industries, such as food, pet food, healthcare & pharmaceuticals and non-food. As an entry-level model, it is particularly suitable for companies that want to switch from manual to automatic carton packaging. Our small all-rounder solves standard packaging tasks and can be used for one-piece packaging as a tray packer and as a wraparound packer.

The benefits of the SOMIC ReadyPack

Discover the SOMIC ReadyPack. An innovative packaging solution that meets all your requirements for efficiency, reliability and quality. The advantages of the packaging machine at a glance:

- Cost-effective and quicker ROI

- Fast delivery and on-site installation

- Minimised error rate and lower personnel costs (compared to manual packaging)

- High efficiency paired with a low space requirement

Efficient packaging made easy

The SOMIC ReadyPack for collating, grouping and packaging products in

- Open cases

- Trays

- Wraparound cases

- Folding cases

- Display cases

Machine process of the SOMIC ReadyPack cartoning machine

- Pre-packed products are fed separately and grouped into case contents.

- The grouping is positioned on the flat case blank.

- The case blank is folded around the entire grouping and secured with hot glue.

- With the wraparound packer model, the top flap is folded and closed.

Compact, versatile and available in no time · Proven SOMIC quality

The SOMIC ReadyPack is a particularly space-saving cartoner and is therefore also ideally suited as an all-rounder for short-term or temporary productions. In the tray packer version, the SOMIC ReadyPack can be expanded to a wraparound packer at a later date if required, thus reliably solving all standard packaging tasks in proven SOMIC quality. Thanks to the flexible format changeover in the specified format range, it is possible to pack different products efficiently with just one system. With the SOMIC QuickChange system, format changes are simple and safe, so that different packaging requirements can be met effortlessly.

Innovative packaging solutions - cartoning machines reduced to the maximum

Which products can be packed with the SOMIC ReadyPack?

The SOMIC ReadyPack cartons products from a wide range of industries. Food and non-food products as well as pharmaceutical products are suitable. Pet food can also be packaged with the cartoner. Regardless of whether you want to pack flour, muesli, snacks, meat and sausage products, baked goods and much more: With our cartoner, you not only increase the speed of packaging, but also ensure a continuous packaging process.

What pre-packaging is the SOMIC ReadyPack suitable for?

The SOMIC ReadyPack is suitable for a wide variety of pre-packed products that are packed upright in cartons. The cartoner is suitable for bags, stand-up pouches, thermoformed packs, folding cartons, tubes, bottles, jars and cans.

How are the products grouped in the cartons?

The SOMIC ReadyPack packs your products upright in open cartons, trays, wraparound cartons, folding cartons or display cartons. Depending on the product size, your products can be grouped in single rows or multiple rows within the permitted format range. You can find our exact format ranges and product dimensions in the data sheet.

Individual support for your success