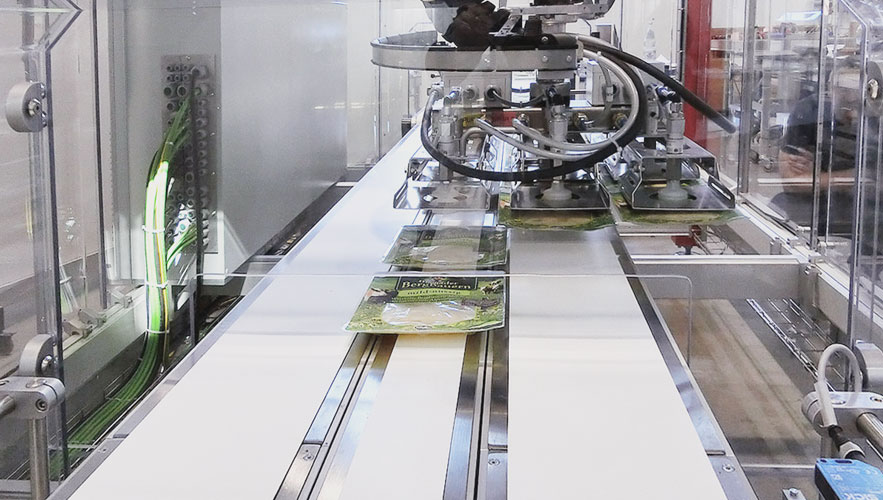

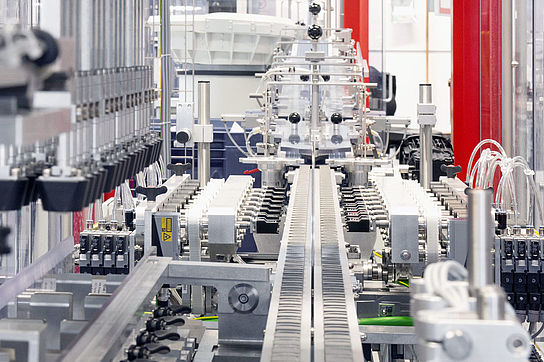

4-axis product manipulator

The product manipulator with 3 servo linear axes and one servo rotary axis is suitable for universal purpose and is used e.g. for amalgamating 5 lines into one.

Sequence

The products are transferred as cut-offs at the interface in max. 5 lines. Cut-offs are always transferred in full (max. 240 individual products). The product lines are transferred in sync. The products are drawn in, rotated 90 / 180° and put down one after another in one line in max. 5 cycles.

Empty individual blisters are not handled. If a cut-off contains empty individual blisters, the complete cut-off falls into a collection container provided by the customer. An individual blister discharge unit can be integrated as an option. The product spacing is not actively influenced.

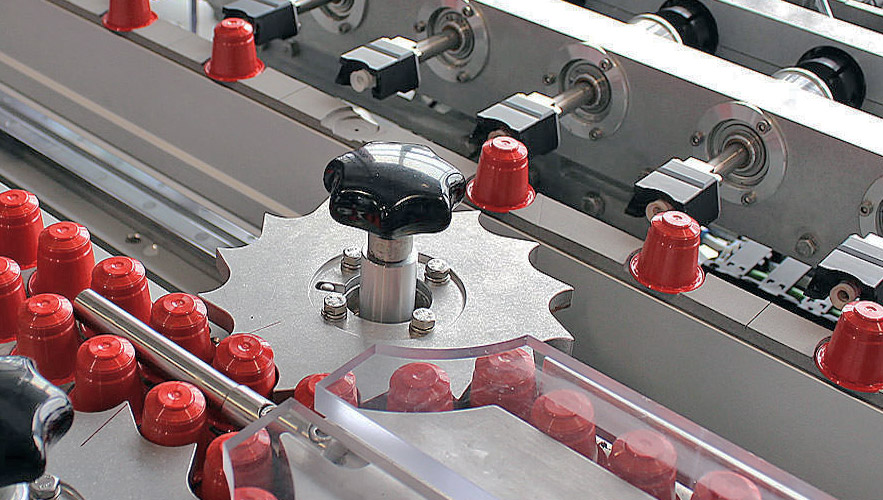

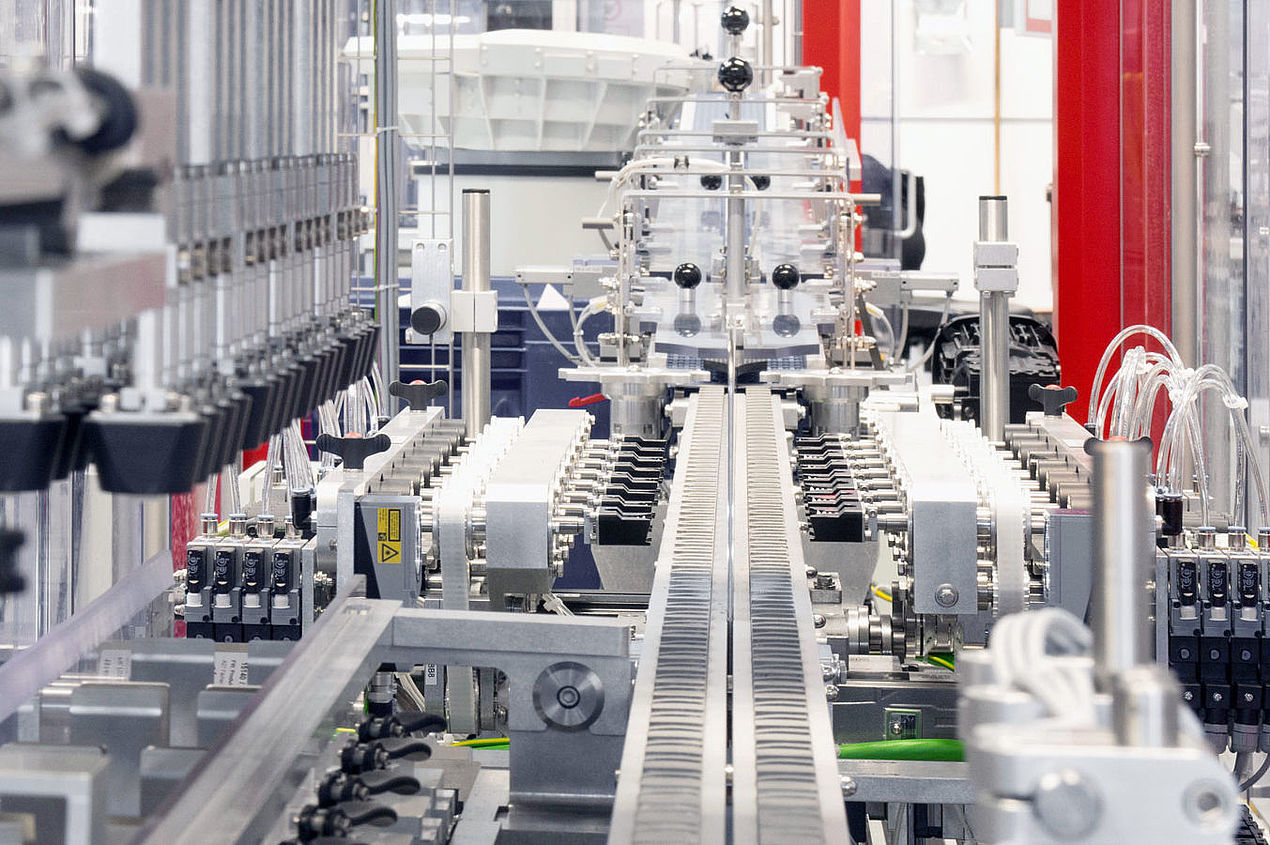

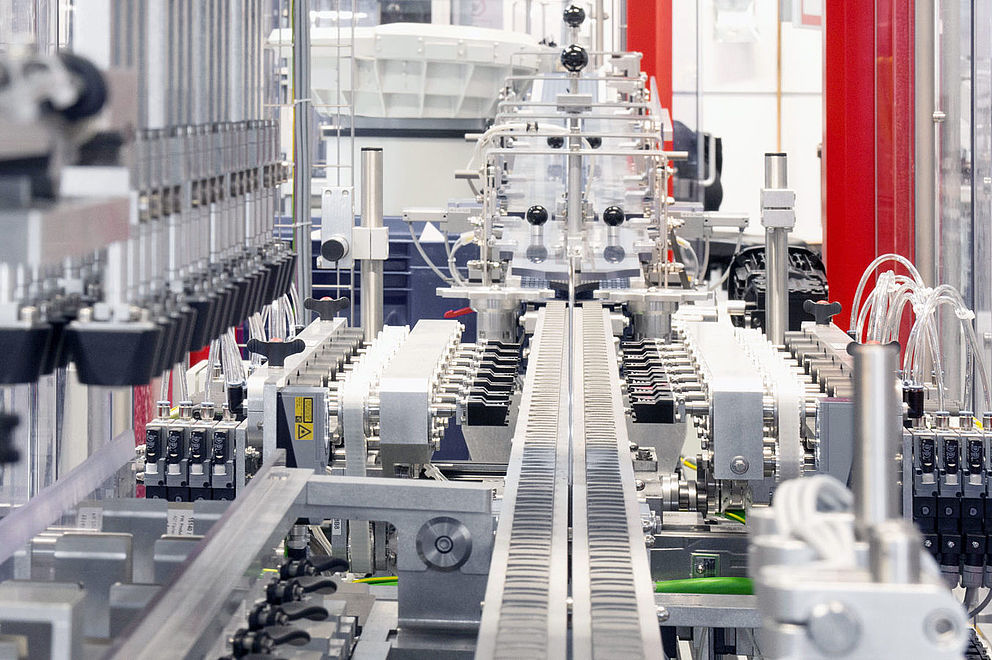

Sequence

The products are transferred at the interface in 2 lines. They are orientated vertically with cover at bottom. After the transfer, some of the products are diverted to a third track. Initially, the capsules of each line are held in a buffer area.

Compensation of quantities using a pneumatically actuated distributor finger evenly distributes the products of the first two lines onto two tracks and supplies each to a discharge star without any gaps. This synchronises the capsules just as evenly and again without gaps to the next toothed belt conveyor.

In parallel to this, the products on the third track are drawn in and turned 180°. They are now oriented with cover at top. The turned capsules are then each put down in the centre of 4 products from tracks 1+2. A group therefore always comprises 5 capsules.

A downstream control device checks that the capsules are in the correct position for the chosen group. If the required capsule position isn’t obtained, this group is not picked up by the transfer head, but instead discharged through a chute. If several groups are discharged directly one after another, an error message is issued and the system stopped.

Other group variants (e.g. group of 11) are possible.

We work for quality suppliers in the food, pet food, pharmaceutical and non-food sectors.

Do you have complex tasks for your packaging line?

We will be happy to convince you with creative ideas and innovative solutions that are precisely tailored to your needs.